In industrial pipeline systems, stainless steel flanges serve as the “connecting core” that ensures leak-proof sealing, structural stability, and long-term durability. Whether in oil and gas drilling, chemical processing, or food and beverage production, choosing the right stainless steel flange can reduce pipeline maintenance costs by 40% and extend system service life by 5-8 years. This guide deciphers key factors for stainless steel flange selection, mainstream types, and practical installation advice to help you avoid common pitfalls in engineering projects.

Why Stainless Steel Flanges Are Indispensable in Critical Industries

Stainless steel flanges outperform carbon steel or cast iron flanges in harsh environments, thanks to their unique material properties: corrosion resistance against acids, alkalis, and saltwater; high-temperature tolerance (up to 870℃ for 316 stainless steel); and excellent weldability that maintains structural integrity. These advantages make them the first choice for industries with strict requirements:

- Oil & Gas Industry: Resist sulfide corrosion in offshore platforms and natural gas pipelines

- Chemical Processing: Withstand corrosive media like sulfuric acid and chlorine

- Food & Pharmaceutical: Meet FDA standards for hygiene and easy sterilization

- Marine Engineering: Tolerate seawater erosion in cooling and ballast systems

Core Material Selection: 304 vs. 316 vs. 316L Stainless Steel Flanges

Material choice directly determines the flange’s service life and safety. The three most common stainless steel grades differ significantly in composition and performance—here’s how to match them to your needs:

| Stainless Steel Grade | Key Composition | Corrosion Resistance | Temperature Range | Typical Applications |

|---|---|---|---|---|

| 304 (SS304) | 18% Cr, 8-10% Ni (no molybdenum) | Good for low-chloride environments (<50ppm) | -196℃ ~ 800℃ | Municipal water treatment, food processing, general industrial pipelines |

| 316 (SS316) | 16% Cr, 10% Ni, 2-3% Mo | 3x better chloride resistance than 304 (up to 200ppm) | -196℃ ~ 870℃ | Chemical plants, marine cooling systems, offshore oil platforms |

| 316L (SS316L) | Low carbon (<0.03%), 2-3% Mo | Superior stress corrosion resistance; ideal for high-corrosion areas | -196℃ ~ 870℃ | Pharmaceutical SIP systems, sulfuric acid transport, nuclear power auxiliary pipelines |

Pro Tip: If your pipeline uses seawater or chloride-based cleaners, 316/316L is non-negotiable—304 flanges will develop pitting corrosion within 6-12 months.

Main Types of Stainless Steel Flanges: How to Choose the Right One

Flange type selection depends on pipeline pressure, connection method, and maintenance needs. Below are the 6 most widely used types in international projects:

- Weld Neck Flange (WN): Features a long tapered neck for high strength. Ideal for high-pressure (Class 600/PN40) and high-temperature systems like power plant steam pipelines. Complies with ASME B16.5 and API 6D standards.

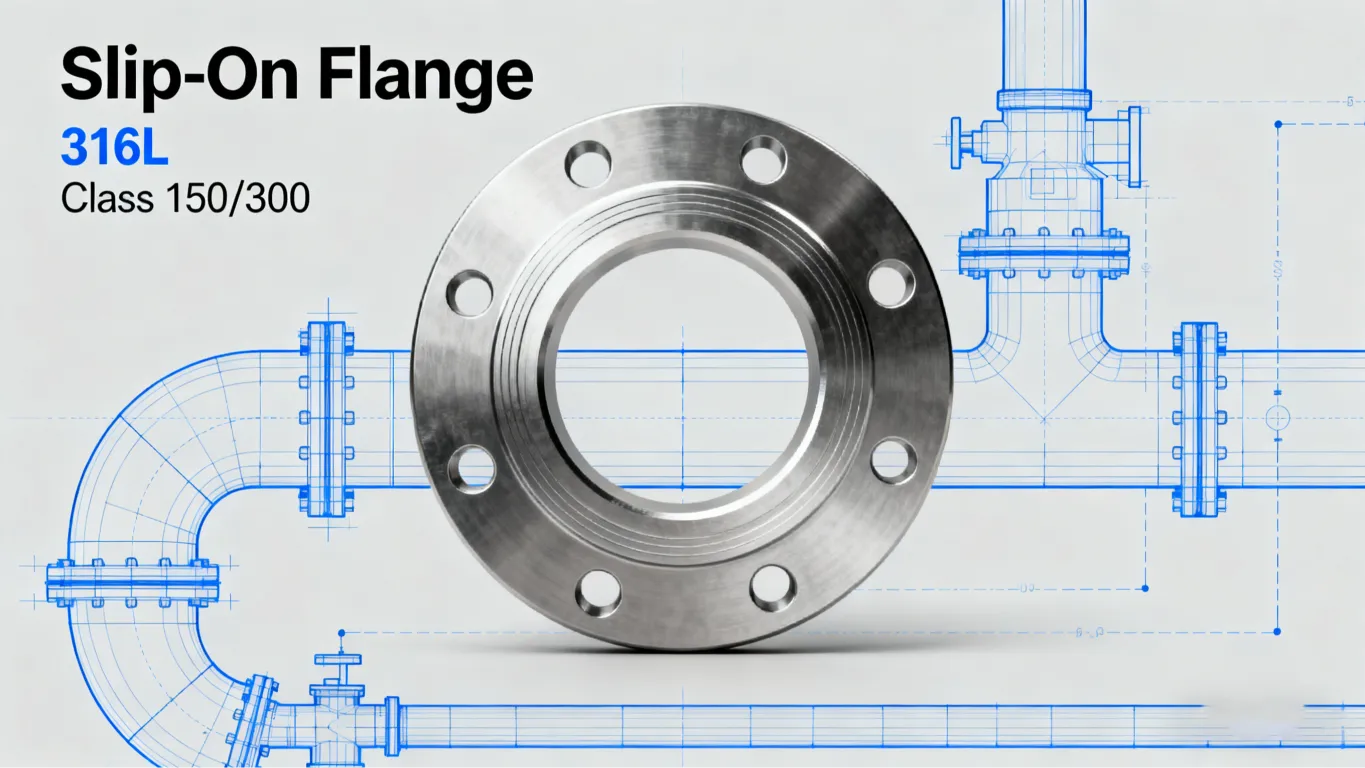

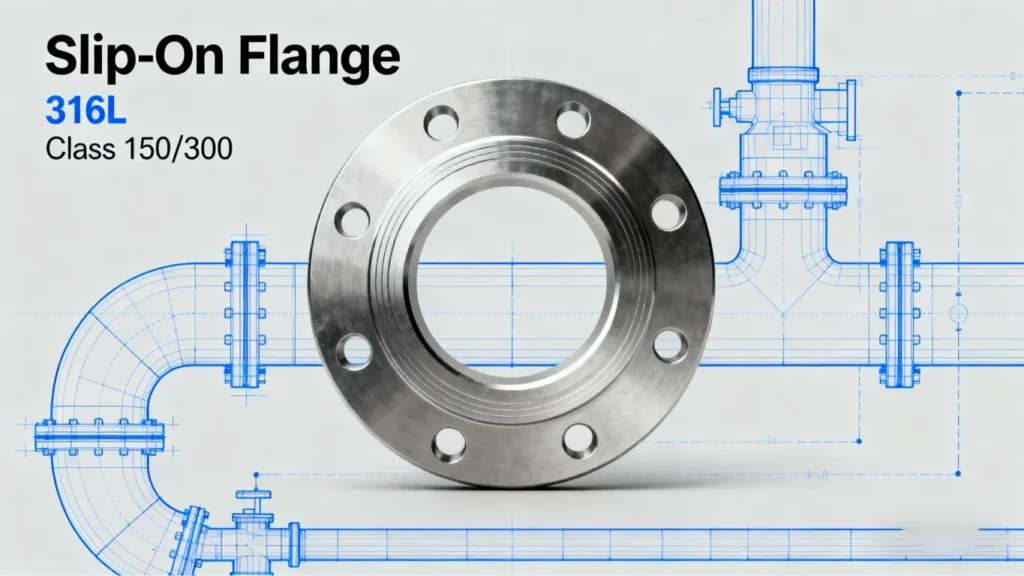

- Slip-On Flange (SO): Easy to install—slips over the pipe and is welded on both sides. Cost-effective for low-pressure (Class 150/PN16) applications such as municipal water pipelines.

- Blind Flange (BL): Used to seal pipeline ends or equipment openings. Common in maintenance shut-offs for oil and gas wells.

- Threaded Flange (TH): No welding required—threads directly onto the pipe. Suitable for small-caliber (1/2″ – 4″) pipelines in explosive areas (ATEX-certified).

- Lap Joint Flange (LJ): Paired with a stub end for easy disassembly. Perfect for corrosive media pipelines that need frequent inspection (e.g., chemical tanks).

- Socket Weld Flange (SW): Designed for small-caliber, high-pressure (Class 300/PN25) pipelines like instrument lines in pharmaceutical factories.

Critical Standards & Installation Mistakes to Avoid

1. International Standard Matching

Global markets have strict standard requirements—mismatched flanges cause leaks and failed inspections:

- North America: ANSI/ASME B16.5 (pressure classes: Class 150/300/600)

- Europe: EN 1092-1 (PN ratings: PN10/PN16/PN25)

- Asia: JIS B2220 (Japanese standard) or GB/T 9112 (Chinese standard, for local projects)

2. Common Installation Errors & Solutions

- Mistake 1: Improper Gasket Selection – Using rubber gaskets for high-temperature (>200℃) systems leads to gasket melting. Solution: Choose graphite or PTFE gaskets for 316 flanges in chemical applications.

- Mistake 2: Uneven Bolt Torque – Over-tightening or under-tightening causes flange warping. Solution: Use a torque wrench and follow the “cross-tightening” sequence (ANSI B16.21 standard).

- Mistake 3: Ignoring Surface Treatment – Leaving welding slag on flange sealing faces causes leaks. Solution: Polish the sealing face to Ra 1.6-3.2μm after welding.

How to Ensure Quality: Key Inspection Points for Procurement

When purchasing stainless steel flanges, verify these 3 critical aspects to avoid counterfeits:

- Material Certification: Request a mill test report (MTR) to confirm Cr/Ni/Mo content—316 must have ≥2% molybdenum.

- Dimensional Accuracy: Check flange thickness, bolt hole spacing, and sealing face flatness with calipers (tolerance ±0.5mm per ASME B16.5).

- Surface Quality: No cracks, pits, or rust—316L flanges for pharmaceuticals should have a mirror polish (Ra ≤0.8μm).

Stainless steel flanges may seem like small components, but they are the “safety valve” of pipeline systems. Choosing the right material, type, and standard not only prevents costly leaks but also ensures compliance with international industry regulations. Our factory supplies 304/316/316L stainless steel flanges in all major types, with full certifications (CE-PED, API 6D, FDA). Contact our engineering team for a free flange selection proposal tailored to your project’s pressure, temperature, and medium requirements.