When assembling industrial pipeline systems, the compatibility between stainless steel flanges and valves is the cornerstone of safe operation. A single mismatch in standards, materials, or certification can lead to leaks, unplanned downtime, or even regulatory penalties—costing oil and gas, chemical, or food processing companies an average of $12,000 per hour in production losses. This guide demystifies the critical factors of flange-valve compatibility, backed by international standards and real-world case studies, to help you avoid costly errors.

First Rule: Never Mix ANSI and DIN Standards—Here’s Why

The two dominant flange standards—ANSI (North America) and DIN (Europe/Asia)—are fundamentally incompatible due to differing measurement systems and bolt patterns. Our engineering team recently resolved a crisis for a chemical plant in Germany where a supplier installed ANSI Class 150 flanges with DIN PN16 butterfly valves, resulting in 12 bolt hole misalignments and a 48-hour shutdown to replace components.

| Key Specification | ANSI/ASME B16.5 Standard | DIN EN 1092-1 Standard |

|---|---|---|

| Measurement System | Inch-based (NPS) | Metric (DN) |

| Pressure Rating Notation | Class 150/300/600 (psi) | PN10/PN16/PN25 (bar) |

| Bolt Circle Diameter (DN50/NPS2) | 120.7 mm | 125 mm |

| Bolt Hole Size | 19 mm (4 bolts) | 18 mm (4 bolts) |

Critical Tip: For cross-regional projects, use adapter flanges certified to both standards. Never force-mate mismatched components—this warps flange sealing faces and invalidates warranty coverage.

Material Compatibility: 304 vs. 316 Stainless Steel Mixing Risks

While 304 and 316 stainless steels are both austenitic, mixing them in flange-valve assemblies can trigger premature corrosion—especially in harsh environments. A nuclear power plant audit found 304 flanges paired with 316 valves in safety injection systems exceeded temperature-pressure limits per ANSI B16.5-1968, requiring a $2.3 million replacement program.

When Can You Mix Them? (Rare Exceptions)

- Low-corrosion environments: Indoor freshwater systems (chloride <50ppm) with 304 flanges and 316 valves—monitor for crevice corrosion quarterly.

- Low-pressure applications: PN10/Class 150 systems with non-critical media (e.g., compressed air) where 304’s cost advantage outweighs long-term risks.

When to Avoid Mixing (Non-Negotiable)

- Marine/coastal areas: 304 flanges corrode 3-5x faster than 316 in seawater (chloride >19,000ppm)—use full 316L assemblies.

- Chemical processing: Acidic or chloride-based media (e.g., sulfuric acid) cause pitting in 304 within 6-12 months.

- High-pressure systems: Class 300/PN25+ applications where 304’s lower temperature-pressure rating creates safety hazards.

Certification Compliance: Don’t Let PED/CE Fail Your Shipment

For EU and global markets, flange-valve assemblies must meet CE-PED 2014/68/EU requirements if operating pressure exceeds 0.5 bar. A U.S. valve supplier recently had a $500,000 shipment rejected by a French refinery because their 316L flanged ball valves lacked PED Category III certification (required for hazardous media).

Key Certification Guidelines by Market

- EU Market: Classify assemblies by risk (I-IV) — Category IV (e.g., oil/gas valves) requires full H1-mode certification with notified body oversight.

- North America: API 6D certification for oil/gas flange-valve systems; ASME B16.5 for dimensional compliance.

- Russia/CIS: EAC certification per TR CU 010/2011 for mechanical safety, including flange bolt torque and sealing performance.

- Food/Pharmaceutical: FDA compliance for 304/316L surfaces; ensure Ra ≤0.8μm polish on flange sealing faces.

Real-World Case Study: How a Refinery Fixed Compatibility Issues

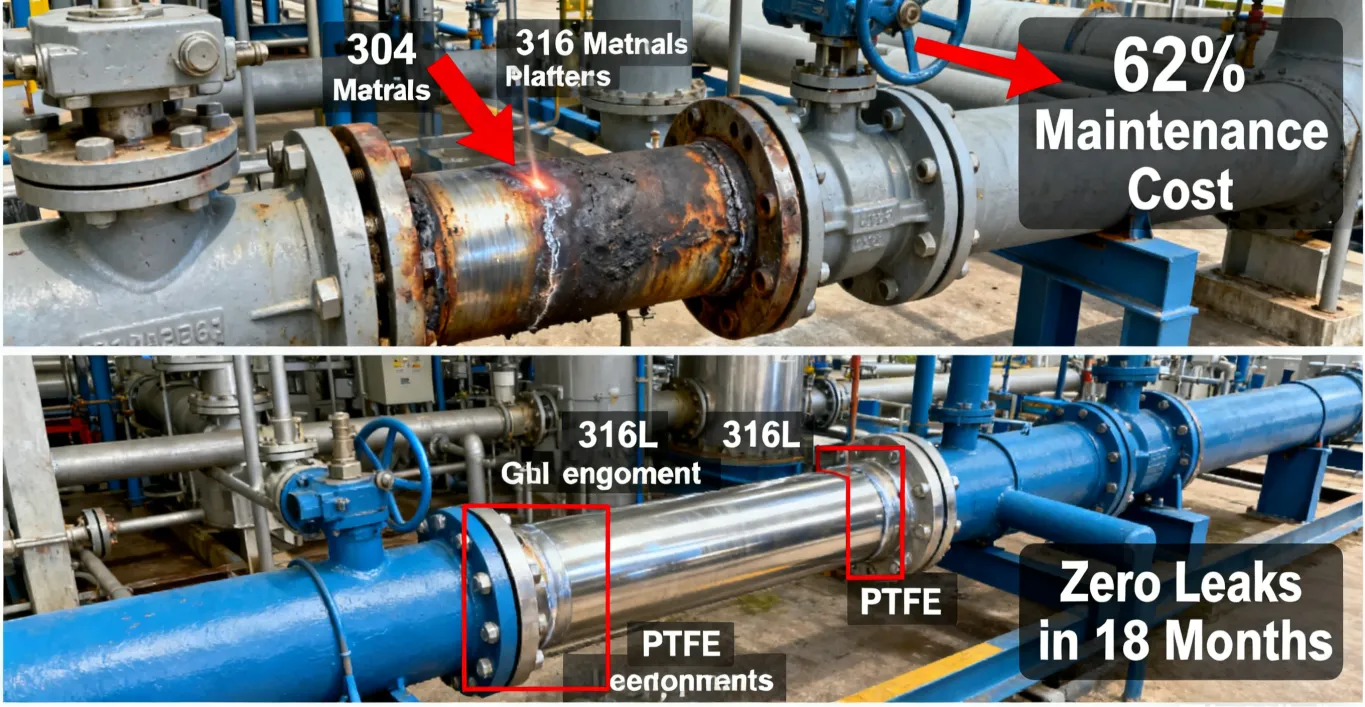

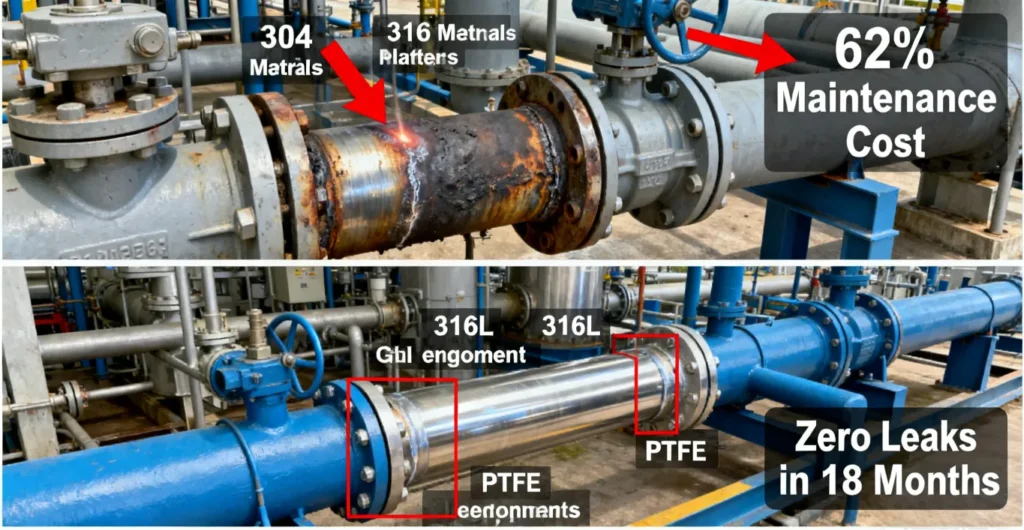

A Middle Eastern offshore refinery faced recurring leaks in their seawater cooling system (316 valves with 304 flanges). Our team implemented three critical fixes:

- Standard Unification: Replaced DIN PN16 flanges with ANSI Class 150 316L flanges to match existing valves (per API 594 face-to-face dimensions).

- Material Alignment: Upgraded all gaskets to PTFE-lined graphite (resists seawater corrosion vs. standard rubber).

- Certification Validation: Obtained PED Category III certification for the full assembly, ensuring compliance with UAE regulatory requirements.

Result: Zero leaks in 18 months; maintenance costs reduced by 62%.

Flange-Valve Compatibility Checklist (Downloadable)

- Standard Verification: Match ANSI/DIN/JIS standards across flanges, valves, and gaskets—use calipers to check bolt circle diameter.

- Material Match: Avoid 304/316 mixing in chloride >50ppm or pressure >10MPa; request MTRs to confirm molybdenum content (316 ≥2%).

- Pressure Rating: Ensure flange rating ≥ valve rating (e.g., Class 300 valve needs Class 300+ flange).

- Certification Check: Validate PED/API/FDA credentials for target markets—never accept “self-declared” certifications for hazardous media.

- Installation Audit: Use cross-torque sequence for bolts (per ANSI B16.21) and inspect sealing face flatness post-installation.

Flange-valve compatibility isn’t just about part numbers—it’s about aligning standards, materials, and certifications with your specific operating environment. Our team provides free compatibility assessments for industrial projects, including 304/316L flange-valve assemblies certified to ANSI, DIN, and API standards. Contact us today to receive your customized compatibility report and avoid costly downtime.