When engineers select valves for high-temperature, high-pressure, or corrosive industrial piping systems, one critical question persists: How to ensure long-term reliable sealing and durability in severe environments? Incorrect material or design choices can lead to leaks, downtime, and even safety incidents. As a specialized manufacturer of industrial metal ball valves, we provide an in-depth analysis of key decision factors to help you make precise selections for critical applications.

Why Metal Ball Valves Are the Default Choice for Industrial Applications

Compared to non-metal valves, metal ball valves offer:

- Superior structural strength to withstand higher pressures (up to Class 1500/PN250 and above)

- Wider temperature adaptability, from cryogenic -196°C to high-temperature +500°C+ service

- Excellent impact and fatigue resistance, suitable for vibrating or pulsating pipelines

- Multiple metal material combinations for customized solutions against corrosive media

Core Decision Points: The Metal Material Selection Matrix

1. Stainless Steel Ball Valves: The Benchmark for Corrosion Resistance

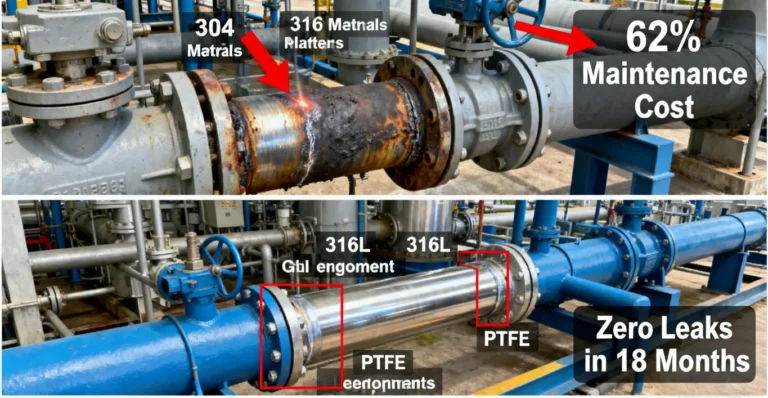

- 304 Stainless Steel: General-purpose, suitable for most water, steam, air, and mildly corrosive chemical media. Cost-effective.

- 316/316L Stainless Steel: With added molybdenum, significantly enhances resistance to chlorides, seawater, and various organic/inorganic acids. The preferred choice for chemical, marine, and pharmaceutical industries.

- Duplex Stainless Steel (2205): Combines austenitic and ferritic advantages, offering extremely high strength and resistance to chloride stress corrosion cracking. Ideal for demanding oil & gas and chemical environments.

- Super Austenitic (e.g., 904L) & Hastelloy: For extreme corrosion environments like strong oxidizing acids and hot concentrated sulfuric acid.

2. Carbon Steel & Alloy Steel Ball Valves: High-Strength and High-Temperature Options

- WCB Carbon Steel: Suitable for non-corrosive media (oil, gas, steam), temperature range -29°C to +425°C. Common in oil & gas and power industries.

- WC6/WC9 Alloy Steel: Contains chromium-molybdenum, excellent for high-temperature creep resistance. Used in high-temperature/high-pressure power plants (e.g., superheated steam lines).

- Low-Temperature Carbon Steel (LCC) & Stainless Steel: Specially treated for cryogenic applications like LNG and liquid nitrogen, preventing low-temperature embrittlement.

Material Selection Golden Rules:

- Step 1: Identify Media – List all medium components, especially chloride ions, hydrogen sulfide, and acid/alkali concentrations.

- Step 2: Define Operating Conditions – Determine continuous/peak working pressure, temperature range, and fluctuation frequency.

- Step 3: Reference Standards – Utilize industry standards like NACE MR0175 (sulfide stress cracking resistance) and ASTM material specifications to narrow choices.

Beyond Materials: Critical Design Features & Certifications That Determine Performance

1. Key Design Features

- Full Bore vs. Reduced Bore: Full bore ensures minimal pressure drop and allows pigging; reduced bore can lower cost and valve torque.

- Fire-Safe Design: Compliant with API 607/ISO 10497, maintaining some sealing capability after fire exposure. Essential for oil & gas industries.

- Anti-Static & Blowout-Proof Stem: Ensures conductivity between ball and stem to prevent static buildup; stem design prevents ejection under pressure.

- Cavity Pressure Relief: Automatically relieves excess pressure in the body cavity to prevent valve rupture.

2. Mandatory Certifications & Standards

- API 6D: International authority for pipeline valves, focusing on sealing performance, durability, and operational safety.

- CE/PED: Required for European market access, ensuring compliance with Pressure Equipment Directive safety requirements.

- NACE MR0175/MR0103: Certification for resistance to stress corrosion in hydrogen sulfide-containing oil & gas environments.

- ISO 9001 & API Q1: Manufacturer’s quality management system certifications, ensuring product consistency.

Professional Installation & Maintenance: Ensuring Design Performance on Your Piping System

Pre-Installation Preparation

- Inspection & Cleaning: Remove end protectors, check internal cleanliness; ensure pipeline connections are undamaged and free of debris.

- Alignment & Support: Perfectly align pipeline and valve flanges to avoid installation stress; provide independent support for large valves.

- Gaskets & Bolting: Select appropriate gasket material (e.g., spiral-wound, graphite), and tighten bolts evenly in a crisscross pattern to specified torque.

Operation & Maintenance

- Actuator Sizing: Accurately calculate valve torque; select suitable pneumatic/electric actuators with limit and overload protection.

- Regular Maintenance: Establish maintenance intervals based on service conditions; inspect stem seals, grease injection systems (if equipped), and cycle valves periodically to prevent sticking.

- Common Troubleshooting:

- Seat Leakage: First verify if system pressure/temperature exceeds limits, then consider seal wear or damage.

- High Operating Torque: Check for media crystallization, excessive seal preload, or bearing damage.

Our Professional Solutions

At [Your Company Name], we specialize in providing high-performance metal ball valve solutions for severe service conditions. Our core strengths include:

- Deep Material Engineering: Beyond standard 304/316 valves, we analyze your specific media reports to recommend or customize the most cost-effective specialty alloys (e.g., Duplex, Inconel), balancing corrosion resistance and cost.

- Expertise in Extreme Conditions: Our product range covers applications from cryogenic LNG to high-temperature +800°C flue gas systems and deep-water high-pressure oil & gas projects.

- Complete Certification Support: We hold API 6D monogram licensing, and our products can be third-party certified to CE/PED, NACE, SIL (Safety Integrity Level), facilitating your entry into global high-end markets.

- Value-Added Technical Services: From reviewing your P&ID drawings, we provide sizing calculations, stress analysis support, and on-site installation guidance throughout the project lifecycle.